Whether production is at the heart of your business

Does your company work third party to produce standard or special items? Does your company design and then manufacture its own components? Does your company have many machining centers to manage? Does your company do all the assembly and have everything done ? Does your company do all these things?

To answer your questions we have created the ideal solution, SolidRules Factum is aimed at companies like yours that want to lead and monitor production to get the most out of their business.

Track performance

All the information needed to assess the trend of production in one place, to always know where to intervene.

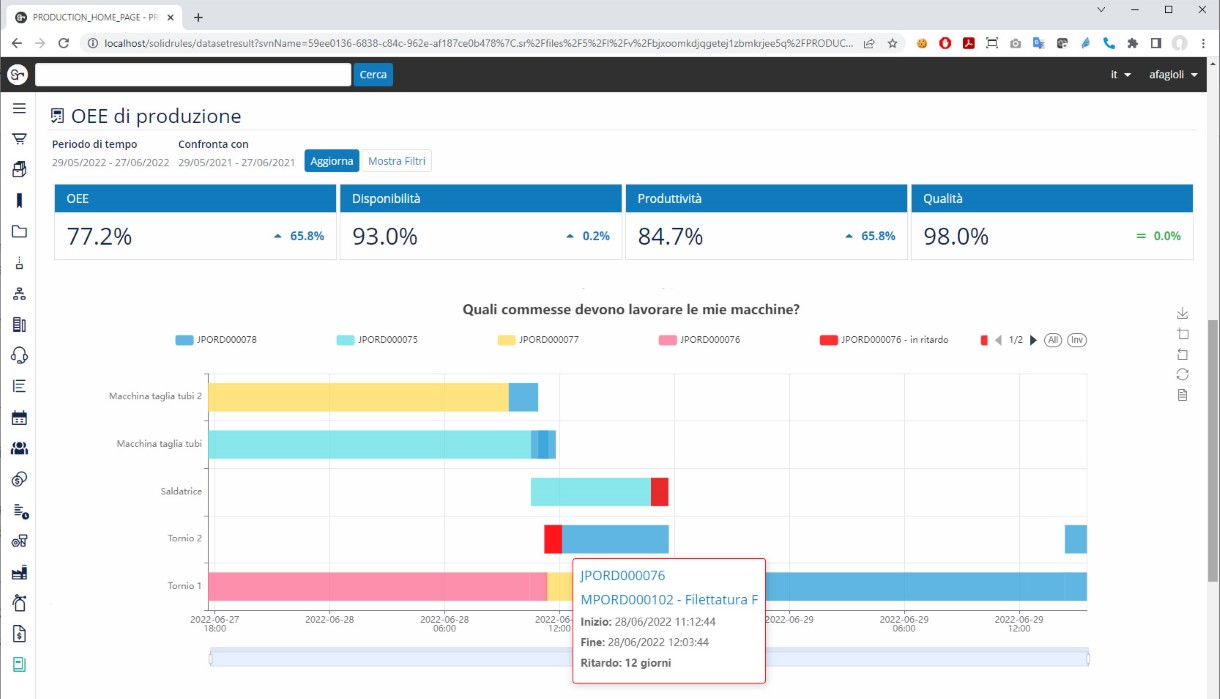

With the production dashboard you can view and monitor the most relevant KPI for you, optimize production quality and improve efficiency. Among the various indicators you will also have the infamous OEE orOverall Equipment Effectiveness that measures productivity, availability and quality.

Indicators and various Gantt will allow you to understand if you can meet the delivery times, you can understand how to reduce the defect, how to reorganize the shifts according to the results and much more.

Manage orders without worries

Reorganize customer orders by determining delivery dates and warehouse stocks. As priorities change, the system simulates new dates based on bills of materials, processing cycles and production orders already in progress. You can also rearrange the priorities of production orders that have already started and see immediately those that will lag behind and those that are ahead of schedule with the customer.

Track production to leave nothing to chance

Each machining centre and operator via pc, tablet or smartphone can manage the start and end of the work phases, enter the product quantities, the waste and make a constant control in Lean optics. Tracking can also be done via barcode or QR Code readers.

The operator will know immediately what he has to do now and where the material produced will have to go. It will know if the job that it is carrying out is online with the time cycle and if it is instead the case to open a report to warn the various agencies that the information of cycle is not reachable and for what reasons.

Not a negligible thing, you cansay goodbye to the paper as it is directly on SolidRules Factum, while you see what needs to be done, you can see the drawing 2D in PDF*, the 3D vector, the tooling instructions, etc.

Express your full potential with Quantum IoT

The system integrates with Industry 4.0 allowing machines to independently manage production progress. With integration with SolidRules Quantum IoT the production manager always knows the production situation and can reorganize it, provide suggestions or report anomalies.

The start and stop of the machining steps can then come directly from the machines.

The SolidRules Factum and Quantum pairing is strategic for meeting the constraints to access the tax credit and for the various measures within Factory 4.0.

Keep an eye on costs and times

On every production order and customer order you can know how much it cost and if you have met the time provided. You can know the costs in terms of design hours, production hours, working hours, material costs and external costs.

Thanks to SolidRules Factum you can also know the value of your stock depending on the various modes (LIFO, *FIFO, etc).

Works great with your PLM

The strong link also with the PDM/PLM world embodied to perfection by SolidRules InCentro allows, for a company that has its own Technical Office, to immediately move from design to production by pouring with a click of the name, bills, cycles, 2D and 3D drawings, setup instructions and everything you need for production.

And this for a company that does special becomes an absolutely strategic fact.

Also if you encounter a problem there is the possibility to open a ticket right on the object to which it refers and all departments are connected by a common thread.

Who is made for

SolidRules Factum is aimed at all those who want to guide and monitor all their production resources so that all processes are executed in the best possible way and in the shortest possible time.

It’s a suitable solution for both those who work for third parties, and for companies that design components and maybe manage the assembly only internally.

And if you do so much special ... then you can’t help but fall in love with him.

Integrations

SolidRules Factum can be totally self-consistent because it manages the production warehouse (WIP) and the various storage warehouses (including automatic ones), it manages the various documents of loading and unloading goods (ddt).

You can start orders to supplier for the work account or for the necessary raw materials.

But SolidRules can live with your ERP system with which it exchanges the necessary information without upsetting your company.

Any question? We are here for you.

Fill out the form or send us an email to info@solidrules.com. We will contact you to provide you all the solutions.