SolidRules V10.5

On December 20, the new SolidRules was released. The new version is the 10.5 but it doesn’t want to be considered as a simple "update". For this reason it is presented with a rich range of novelties.

- The new SolidRules Quantum for the IoT

- New and incredible analysis tools (KPI, graphs, BI)

- Project costing through time and material management

- Machine service management in production

- Medical examination, safety and training management

- New time and cost management

- Integration with Creo Parametric

- New management of spare parts

- An increasingly powerful production management system

- Integration with Outlook 365

- Performance improvement

- Strengthening the research system

- Bill of materials costing by AI techniques

- Improved usability on mobile devices

- Signature pdf and sequential and parallel workflow

- Support for Solidedge, Solidworks, Inventor 2020

IoT for those who are not afraid to dare

With SolidRules Quantum makes its debut an ideal system for the management of IoT needs in Industry 4.0 optics.

It is not simply the classic Internet of Things but rather an Intranet of Things. Those who choose it can have everything internally without the need for external Cloud services that manage and analyse data. These systems are beautiful (maybe nice) but if you decide to change Cloud service you don’t just have to move the data to another server, you have to redo the implementation. In addition to this, costs are related to consumption and can vary over time in an unpredictable way.

The SolidRules Quantum proposal allows you to have a completely different point of view where you decide and not someone else you can’t control!

At the beginning the system is presented with:

- Real time measurement and alarm reading

- Historicization of all measurements through a refined time series database

- Historical data analysis with KPI and graphic management for those who really want to do predictive maintenance, evaluate the return on their investment or understand how to optimize the production process.

We have already successfully integrated the machines of the main vendors on the market without the need to use external hardware/software mechanisms.

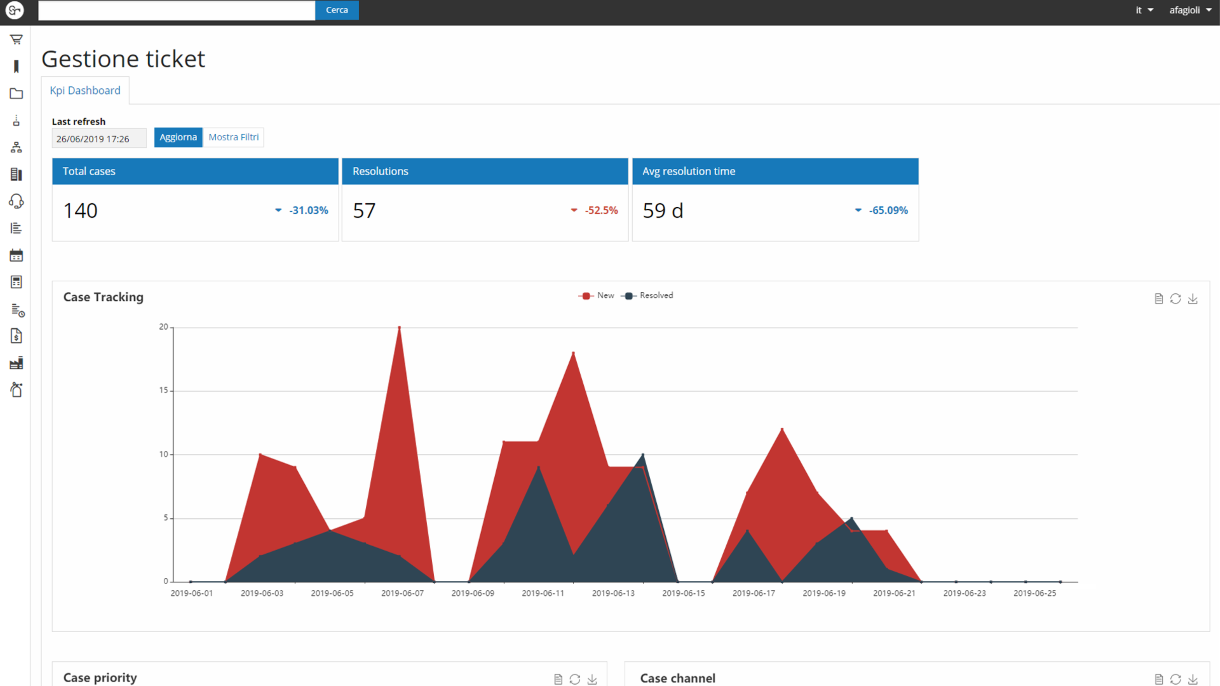

Analysis

We decided to bring the powerful analytics system developed for Quantum to the Desk as well. Business Intelligence becomes for everyone.

We have included standard indices and graphs for your daily needs and this allows you to evaluate, in real time, the performance of your company in all departments. You can build new indices and graphs by yourself.

And if this incredible power is not enough for you, and it will, it is very simple to export data managed from SolidRules in normal formats and immediately usable for external systems of Business Intelligence.

The possible outputs can be of different types like for example csv, excel rather than sqr.

The dashboards and KPI standards right in the moment you implement Desk are going to cover the needs of all these depatments:

- Assistance

- Service

- Planning

- Selling

- Accounting

- Production

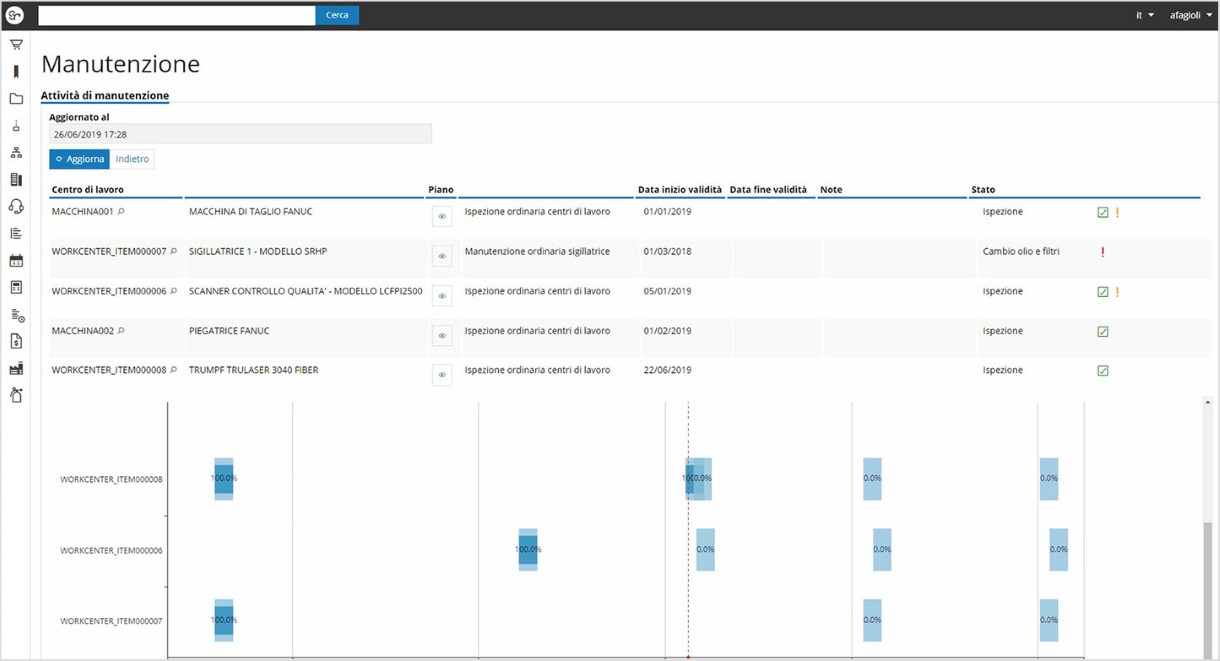

Service System

The service system is enhanced by the management of maintenance of your machine meant for everyone that have an internal production or simply for those who want to program the services based on a maintenance plan.

The Maintenance Plan defines how much the machine must be subjected to programmed intervention (time or counter). The maintenance plan also defines the checks to be made and the spare parts suggested.

On the basis of the maintenance plan it is possible to schedule the interventions for the machine or for all the machines of the company.

The ability to immediately see all the documentation associated with the machine makes the system unique and usable by maintainers even from a smartphone.

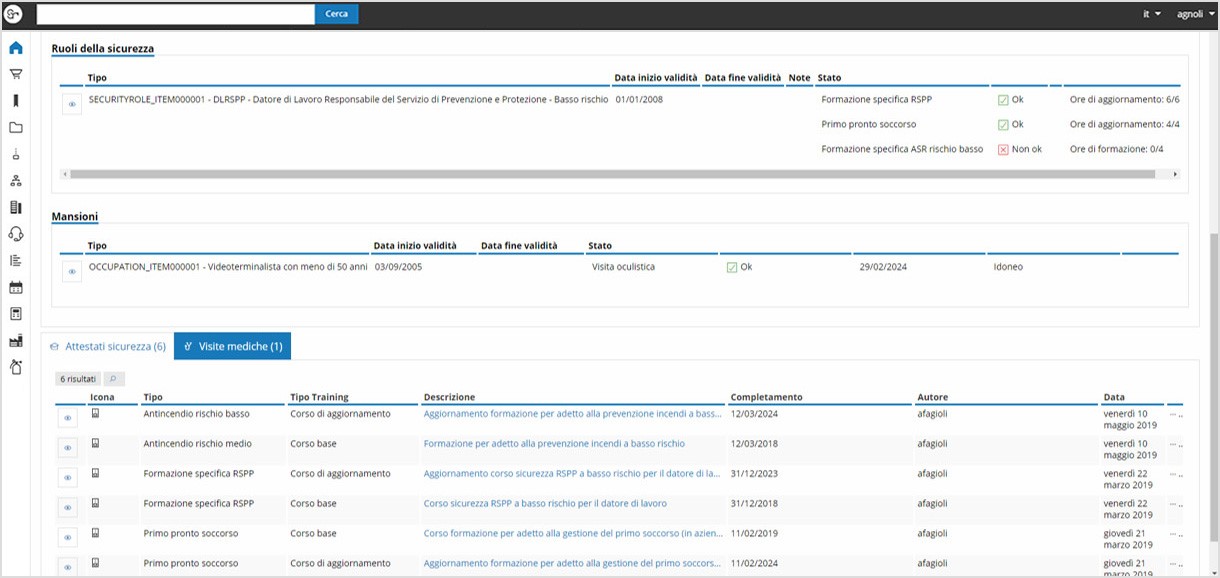

Safety, health and education

Similar to what has been done for the maintenance of the machines, new elements have been introduced designed to manage the needs of Human Resources (HR) related to medical examinations and staff training with particular emphasis on safety-related courses and requirements.

For health care there was introduced concepts of:

- Tasks – a specific job involves certain medical checks and well-defined deadlines

- Medical examinations - medical examination results are recorded

For education there was introduces:

- Security roles - depending on the role there are certificates to be obtained with deadlines for updates

- Safety certificates - to keep track of training

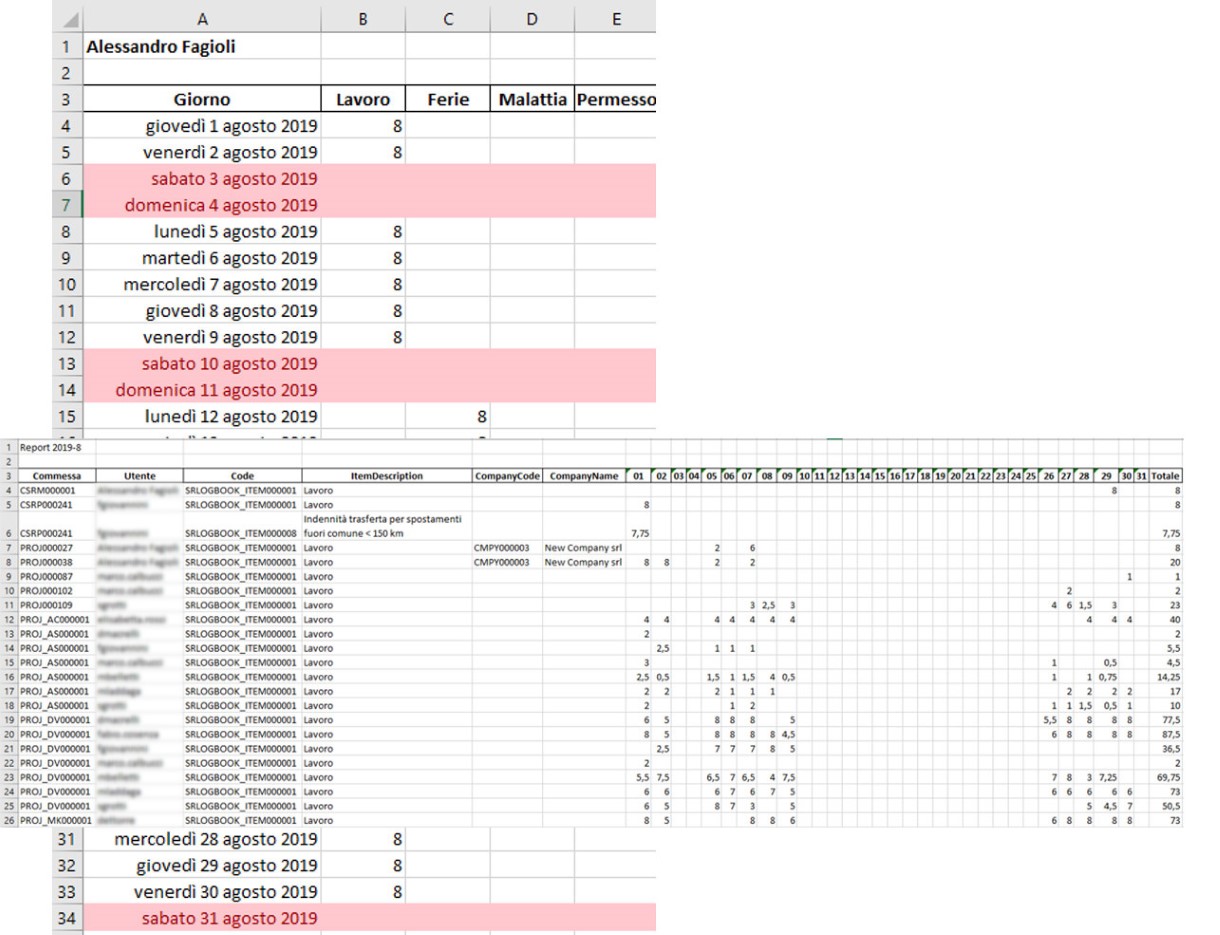

Management of costs and time

The Logbook has been introduced. It retrieves information from events, interventions, activities and projects to produce, in combination with the new analysis tools, strategic documents such as:

- Employee hours report for payroll

- Report on travel reimbursements

- Hours report per order

- Cost per contract report

To properly manage the hours on each person it is now possible to define specific calendars in order to know when the person usually works.

Managing orders

A new order management system has been developed in order to keep costs under control in addition to the scheduled and actual hours.

This management allows you to monitor expenses and revenues and allows you to better manage planning for companies working on a contract.

The management of the project has been strengthened through several interventions such as the support of the links between the phases (Beginning with End, Beginning with Beginning).

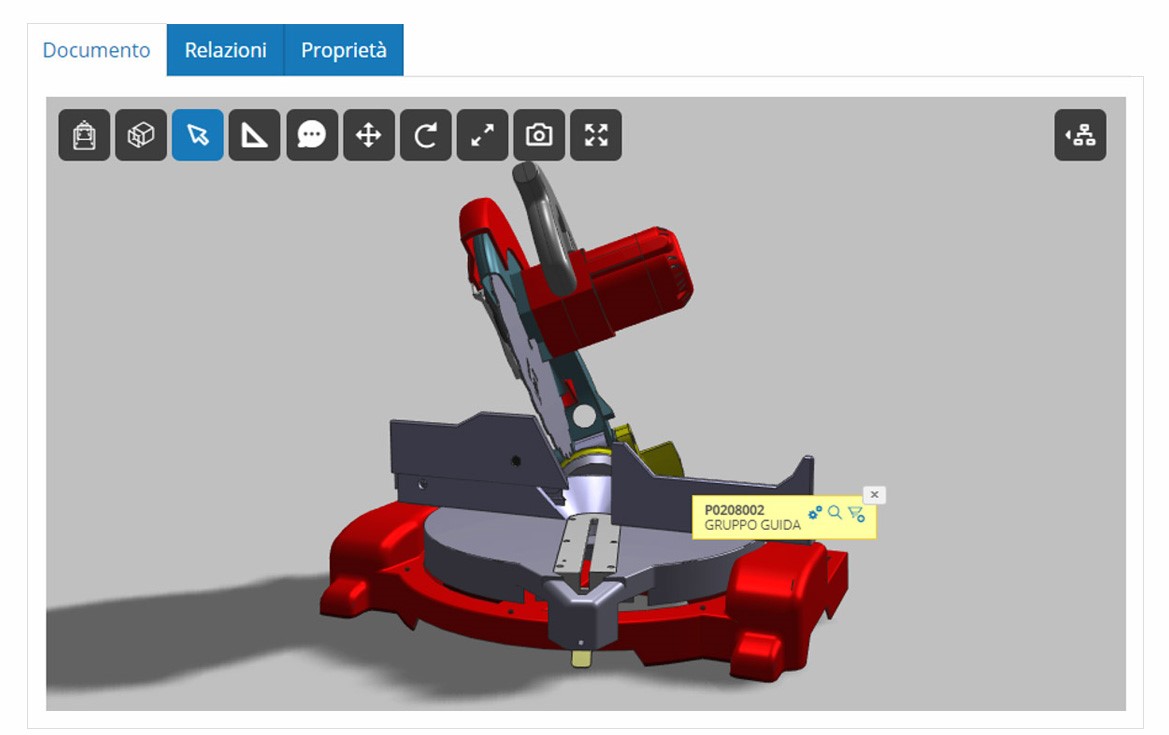

Creo Parametric

With the addition of Creo Parametric we are expanding the wide range of mechanical CAD supported. Taking into account the integrations realized with all the main electrical CAD, with more than 50 brands of different management systems it is understood how the choice of SolidRules is possible for an increasing number of companies.

The support to Creo Parametric passes from the PDM world but touches the world of technical configuration of product, one of the strategic assets of SolidRules.

Costing with AI

We are applying Artificial Intelligence techniques in various areas. This anticipates the V11 of SolidRules where these techniques will affect the daily work of all SolidRules users.

We have developed a system able to estimate the assembly times from the analysis of the bills and assembly times detected in the past.

This has been achieved by training a model with historical data so that it is now possible to estimate assembly times in advance against a new bill of materials.

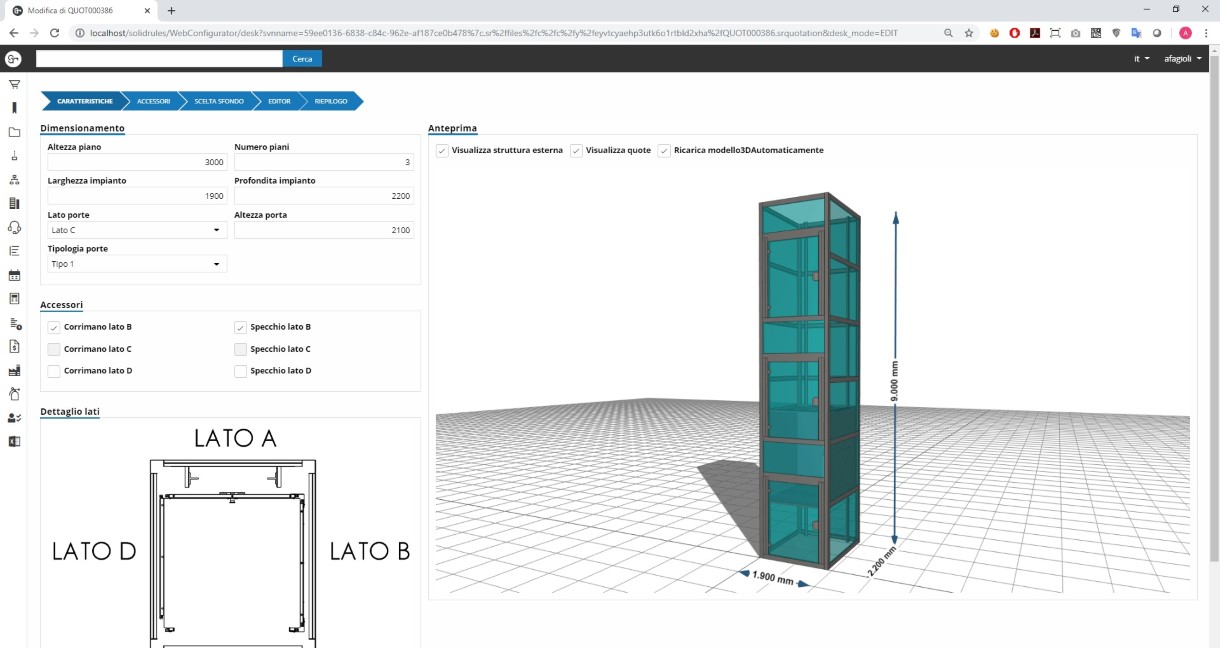

Planner

The functions of the Client Planner are now all available on Web to have an unlimited configuration experience and therefore available on PCs, tablets and smart-phones.

The material management has also been completely revised and this has allowed us to obtain a much more realistic graphic rendering.

Manufacturing

New spare parts management

The production of spare parts has been completely revised in order to obtain greater flexibility. Thanks to the new implementation on spare parts, companies can get the same possibilities of adaptation to the objectives offered by the DESK.

The approach remains unchanged, that is to allow to manage the spare parts from any object, a production list, a parts list, a spare parts sheet, a material list…

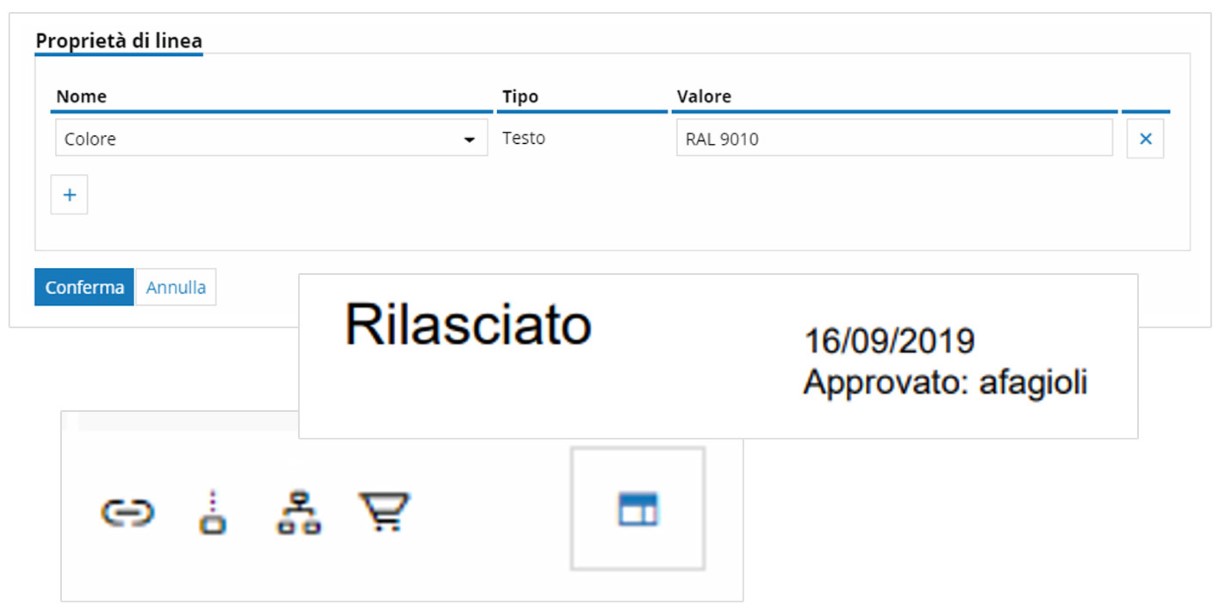

The news about SolidRules continue!

- It has been introduced the management of the attributes of line that offers a greater power on the various tables

- You can add texts to the PDF on the server side. For example, it can be useful for reporting document approvals

- SolidRules is also integrated with Office365 and calendars can be synchronized with that system in a similar way to what is done for Google

- New non-conformity management of Product and Process

- Improved the overall performance

- Further improvement in research effectiveness

- Enhanced the entire management of the production MES

- More than 100 user improvement requests implemented

But you won’t have to wait too long for SolidRules V11

The V11 is well on track and if you can’t find the news you want in the roadmap, it’s time to step up. You want your request to come true?

- New organization of the Client and Web interface to highlight the code

- Studio Web with the possibility to write the rules with the maximum possible dynamism

- New management of settings in the name of simplicity

- Lean oriented management

- New time line

- SolidRules Web app and app

- New audit management

There is another news under the hood of the V11 but we can’t give any spoiler ;-)

Any question? We are here for you.

Fill out the form or send us an email to info@solidrules.com. We will contact you to provide you all the solutions.